If your lithium battery’s power supply time is short, it may be caused by insufficient battery capacity. This not only affects power consumption at night and on rainy days but also shortens the service life of lithium batteries.

A lithium battery that lasts 12 years may have its service life shortened to 6 years or even less due to long-term over-discharge.

You may need to add more after-sales costs to replace lithium batteries, making the return on investment even lower.

With the dazzling array of lithium battery brands on the market, how should we choose?

Test the lithium battery capacity

This is one of the most intuitive and reliable ways.

Through testing, you can see whether the lithium battery has 100% full capacity.

PVMars Solar Energy Company will use a 5kWh (51.2V 100Ah) lithium battery as a sample: connect the battery to a DC and AC inverter to output electric energy to power 220V electrical equipment (load).

Then use a multimeter to circle the wires of the output port and measure the output current, which is approximately 21.6A.

According to the physical formula, capacity (Ah) divided by output current (A) equals power supply time (H).

Through calculation: 100Ah / 21.6A = 4.6H. If it is a lithium battery with a full capacity of 100Ah, the test results will take about 4 and a half hours to discharge the energy in the battery.

Less than 4 hours indicates insufficient capacity.

So what is the actual situation?

From the video, we can see that the PVMars 51.2V 100Ah lithium battery has 100% full capacity.

In addition, other factors affect the rapid consumption of lithium batteries’ capacity. Continue reading this article to learn more.

Tips: Click on the picture below to watch the test process.

Factors affecting lithium battery capacity

Insufficient or excess negative electrodes, production process, raw materials, usage environment, and charging state. These aspects can also affect the problem of excessive capacity consumption of lithium batteries.

1- Excessive and insufficient negative electrode

In the manufacturing process of lithium batteries, the amount of negative electrode material has a major impact on the battery’s performance.

Excessive or insufficient negative electrodes will cause lithium to precipitate on the surface of the negative electrode, forming a thin layer of lithium.

This phenomenon will reduce battery capacity and charge and discharge performance.

The higher the negative electrode excess, the positive electrode’s performance will decrease, but the probability of this happening is smaller. To solve this problem, battery performance can be optimized by reducing fluid injection.

However, the premise must be to ensure the performance of the battery core. The liquid injection volume cannot be blindly lowered simply to lower costs and process pressure.

2- The production process

If the production process is abnormal, it will cause another serious reason for the low battery core capacity.

During the production process, errors in any link may lead to a decline in lithium batteries’ performance.

For example, the positive or negative electrode coating is too light. There are problems with the positive and negative surfaces, damage to the material structure by rolling, excessive water content, etc.

May cause low capacity.

Among them, the light coating of the positive electrode will directly affect the battery’s capacity and stability.

When the possibility of excessive or insufficient negative electrodes is high, it can be judged by comparing the relative weight ratio of single and double sides after baking.

The problem of Yin and Yang surfaces is caused by uneven coating and can be solved by optimizing the coating process. Exceeding the water content will destroy the SEI film and consume lithium salt, reducing battery capacity. Therefore, it is crucial that the various parameters in the process.

To better analyze the reasons for poor capacitance, we need a detailed analysis of process data, cell comparison, etc.

To establish a basis, it is necessary to repeat experiments or collect process abnormality data for unseen low-volume situations, especially if the process is unknown.

When analyzing the causes of low capacity, various possibilities should be fully considered and the correctness of the assumptions should be verified through experiments.

Only in this way can we truly understand the reasons for lithium battery cells’ low capacity and find effective solutions.

PVMars has summarized 10 aspects that require special attention during lithium battery production. If you are interested, you can click on the orange text to jump to related articles.

3- Raw materials

In addition to production process factors, lithium batteries’ material quality is also one of the key factors affecting their capacity.

Material responsibilities include the selection of positive electrode materials, the purity of negative electrode materials, and the properties of the electrolyte.

Parameters such as the crystal structure, particle size, and morphology of the cathode material will impact the insertion and extraction of lithium ions.

This will affect the battery capacity.

Insufficient purity of the negative electrode material or impurities will increase the battery’s internal resistance and reduce its capacity.

The conductivity, stability, and compatibility of the electrolyte with electrode materials will also impact battery performance.

Therefore, choosing the right materials and ensuring their quality is the key to increasing lithium batteries’ capacity.

PVMars purchases raw materials from major international brands. Including but not limited to BYD, CATL, Ganfeng, etc.

4- Choice of CTP, square and round batteries

PVMars’ energy storage system uses lithium iron phosphate batteries (lifePO4), called LFP.

It is the choice with the maximum safety performance and longest life among many lithium-ion materials.

For a detailed explanation, please refer to the article “What kind of lithium batteries are more suitable for renewable energy systems?“

Blade, square, and round shapes are all suitable for lithium batteries.

However, square cells are the ideal form for LFP chemistry, and there are strong signals that LFP square cells are emerging.

In Asia, electric car manufacturers use LiFePO4 batteries, a square form of LFP battery. Tesla also said it uses Chinese-made square battery cells in standard-range cars.

Due to the low energy density of square batteries, in 2020, blade batteries were born.

It is also called a CTP battery pack (Cell to Pack) since the cells are directly packaged into the battery pack.

A single soft-packed battery cell is made into a thin and long blade shape and directly packaged into a battery pack.

The main feature of the CTP battery is the improvement in the manufacturing process. This arranges more cells in a limited space, increasing the battery’s energy density.

CTP battery pack increases energy density and reduces components. And its disadvantages are reduced anti-collision performance, a complex production process, and high cost.

So, the current mainstream still consists of prismatic batteries.

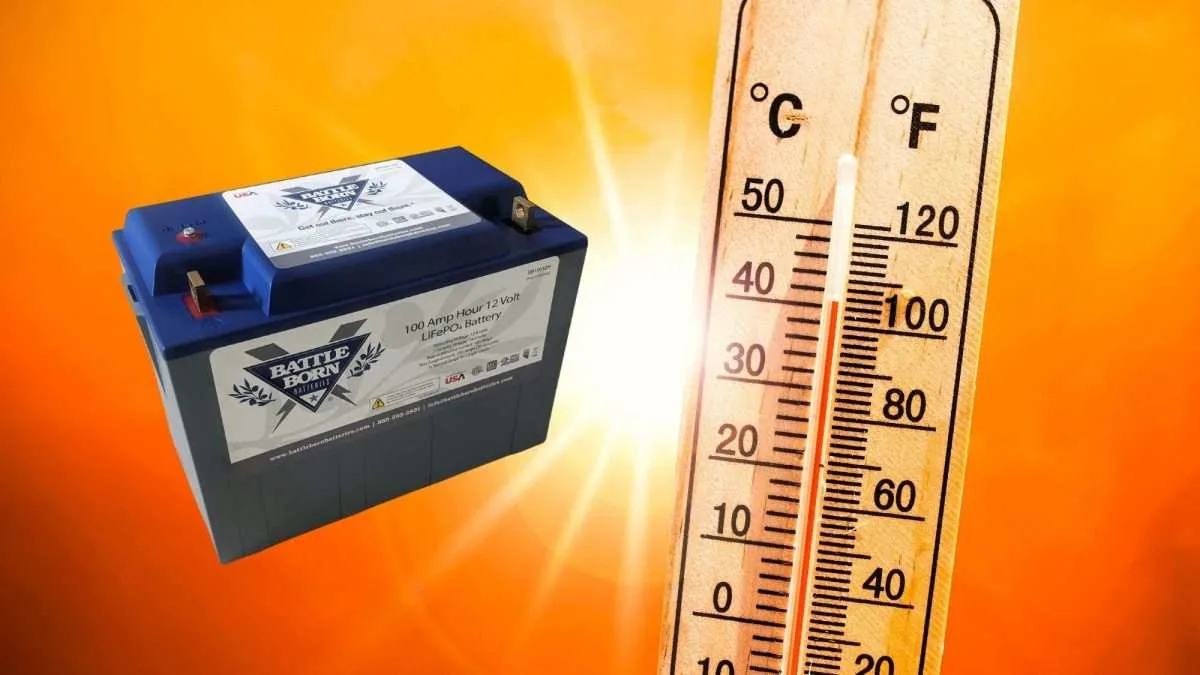

5- The environment in which lithium batteries are used

Environmental factors also affect lithium battery cell capacity. Temperature is one of the most critical factors.

In a high-temperature environment, the electrolyte will more easily penetrate the electrode material and accelerate the battery aging process.

Low temperatures will increase the viscosity of the electrolyte and reduce the migration rate of lithium ions, thus affecting battery capacity and charge and discharge performance.

It’s important to keep lithium batteries at the right temperature when using and storing them.

This will extend their service life and maintain a stable capacity. Lithium batteries can adapt to temperatures -10°C to 55℃.

For 215kWh-3MWh energy storage lithium battery systems, PVMars designed HVAC to effectively cool down and control the operating temperature of the battery.

This is so that you can use it smoothly no matter what your environment is.

But if there is no energy storage cabinet design, for example, PVMars has installed a 200kW solar system at 4,000 meters altitude. This system uses 2V colloidal lead-acid batteries, not lithium batteries.

In winter, the temperature in high altitude areas will fall below -10°C, which is not conducive to lithium battery discharge, resulting in insufficient capacity.

After suggestions from senior PVMars engineers, the lithium battery was replaced with a gel battery.

This is more suitable for low-temperature areas and more cost-effective than lithium batteries.

6- Charging status

The state of charge also has a significant impact on lithium batteries’ performance.

Overcharging will change the cathode material structure and accelerate the battery capacity decline.

Excessive discharge will lead to the depletion of lithium ions on the surface of the negative electrode.

This will lead to the formation of lithium dendrites, which will reduce battery capacity but also cause safety issues.

Therefore, it is very critical to keep track of lithium batteries’ charge state. Smart charging technology can prevent overcharging and over-discharging problems, extend battery life, and maintain stable capacity.

Each set of PVMars LFP batteries comes with a BMS, which, when paired with the IOT system in the solar system, can remotely control and eliminate overcharging and discharging problems in the energy storage system.

And the PVMars team in China can monitor and maintain your system security 24/7.

Let's summarize

To sum up, there are many reasons for inadequate lithium battery cell capacity.

To improve the battery’s capacity and stability, we need to have an in-depth understanding of the impact of production process factors, materials, the usage environment, charging status, etc.

The problem of insufficient battery capacity can be effectively solved by optimizing the production process.

This is done by selecting high-quality raw materials, maintaining a suitable ambient temperature, and controlling charging status.

But if you increase the load, the battery capacity will also be reduced. You can click “Battery Supply Time” to find out which battery is more suitable for you, and then purchase the correct lithium battery.

At the same time, PVMars will continue to strengthen basic research and technological innovation. The development of lithium batteries can also be promoted in this manner.