With growing concerns about energy shortages and power outages, renewable energy sources such as hydropower, wind energy, and solar energy are receiving increasing attention.

It is predicted that in 2050 renewable energy will become the primary energy source, with an average annual growth rate of 3.6%. Solar and wind energy are expected to account for 70% of the total renewable energy output.

However, the fluctuating and intermittent nature of the electricity generated by these renewable energy sources makes them challenging for practical applications.

Electric energy storage is a powerful tool for increasing the flexibility of integrating renewable energy into the grid, improving grid reliability, optimizing the utilization of renewable resources, extending the service life of infrastructure, and enhancing power quality.

Batteries can store the electrical energy generated by renewable sources. In the form of chemical energy, convert it into the necessary electrical energy. Therefore, battery technology can accelerate the adoption of renewable energy.

Among them, the flow battery has the characteristics of high capacity, a wide range of applications in various environments, and long cycle life.

The most notable feature of flow batteries is their ability to store large amounts of power storage.

Under the widespread use of renewable energy, it is foreseeable that flow batteries will experience a period of rapid development.

How does a flow battery solve power outages?

First, let me introduce the characteristics of a flow battery. The electrolyte of the battery is an aqueous solution, and the reaction site is separate from the storage site of the active material.

The stack is a type of container used for electricity stack, while the liquid storage tank is designed specifically for storing liquids. They will not catch fire or explode, so their safety is very high.

All flow batteries, including all-vanadium flow batteries, iron chromium, and zinc-bromine, can be charged and discharged 100%.

Even if its charge and discharge depth reaches 100%, it will not cause any damage to the battery, but it will actually be beneficial to the battery’s lifespan.

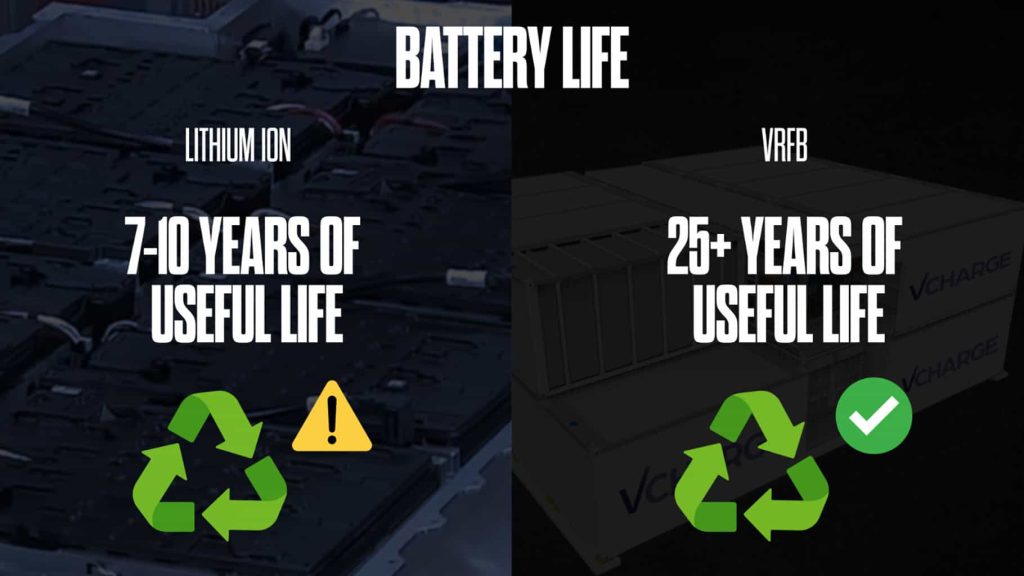

This aspect is compared with lithium batteries because it overcharging or over-discharging them can result in irreversible damage, internal short circuits, or even fire and explosion.

Therefore, lithium battery is not possible to charge and discharge fully.

Secondly, the capacity and power of the flow battery can be independently configured. This is also the most appealing aspect of the flow battery.

For the flow battery, the output power of the entire system is determined by the number of stacks, while the capacity of the entire flow battery system is determined by the amount of electrolyte.

The Reaction Principle of Vanadium Redox Flow Battery

The battery stack of an all-vanadium liquid flow system is composed of end plates, bipolar plates, current collector plates, graphite felt, ion exchange membranes, and sealing rings.

The chemical involves the reaction of 1-valent vanadium and 2-valent vanadium at the positive electrode, and the reaction of 3-valent vanadium and 2-valent vanadium at the negative electrode.

During the reaction, vanadium can be converted from 3-valent to 2-valent, or from 1-valent to 2-valent conversion.

The exchange of electrons occurs through electrodes, while the middle diaphragm facilitates the exchange of protons, also known as hydrogen ions, creating a cyclic process.

Because the power consumption of the externally driven pump affects the efficiency of the entire process, the efficiency is relatively low. However, its safety factor is relatively high.

Even if the middle layer of the film is punctured or there are any issues, it will not result in a short circuit or fire inside.

The flow battery is at most after the electrolyte is mixed, and the electrolyte is re-prepared, and then the entire stack will not be completely damaged.

In lithium batteries, if there is a problem with the separator, essentially the entire battery will be destroyed.

Types of Flow Batteries:

1- All vanadium redox flow batteries

Its electrolyte is an aqueous solution of vanadium particles that does not burn or explode.

The electrolyte is formed by dissolving vanadium pentoxide in dilute sulfuric acid, and the heat can be effectively dissipated.

After the electrolyte reacts, the heat can be effectively dissipated through the heat exchanger, and the efficiency of this heat dissipation will be much greater than that of the lithium battery’s heat transfer.

Secondly, it has a long service life. In the process of charging and discharging, the electrode material only serves as an interface and does not actively participate in the reaction.

As a result, it can maintain a stable state over an extended period of time. 100% charge and discharge have no adverse effect on the performance of the battery and even have a positive effect on it.

The influence of temperature on capacity can be missed, but it is not absolute. The operating temperature of an all-vanadium liquid flow system is typically between 10℃ and 40℃.

If the temperature is too high, some precipitates will form and adhere to the proton exchange membrane during circulation.

This, in turn, reduces the efficiency of the entire system. Therefore, it is usually necessary to provide a system for regulating the temperature.

The capacity of this type of battery is recoverable, and the valence imbalance caused by its minor side reactions can be restored through redox adjustment.

2- Fe-chromium liquid flow energy storage system

The FeCr flow battery energy storage system is characterized by its long lifespan, with a cycle count exceeding 20,000.

Secondly, it is environmentally friendly and has a high level of safety. The electrolyte and the materials of the positive and negative electrodes have low toxicity and corrosion.

This advantage is compared with the all-vanadium liquid flow battery. And it is renewable, safe, stable, and highly efficient.

The efficiency on the DC side is greater than 80%, while the efficiency on the AC side is greater than 70%, making it a leader in the industry.

The adaptability of liquid iron-chromium flow is relatively strong, which is its unique advantage. It is better than all-vanadium liquid flow batteries.

Its working temperature can range from -20℃ to 70℃, which is a significant advantage compared to all-vanadium liquid flow.

3 – Zinc bromine liquid flow battery

Zinc-bromine liquid flow was first invented by an oil company. It is a high-performance, low-cost, and large-capacity energy storage system.

The electrolyte used in this battery is a solution of zinc bromide. The battery is divided into a positive half-cell and a negative half-cell by a diaphragm.

These half-cells are connected to the positive and negative electrolyte storage tanks, respectively.

Under the action of the circulation pump, the electrolyte circulates in a closed loop formed by the storage tank and the battery, facilitating simultaneous redox reactions.

Zinc-bromine flow batteries and vanadium flow batteries are both characterized by separate positive and negative solutions, which operate independently, eliminating the issue of cross-contamination.

However, there is a problem of cross-contamination in the iron-chrome liquid flow.

The zinc-bromine liquid flow battery can achieve relatively low costs, as the key components, including electrodes and diaphragm materials, are mostly made of plastic.

This makes them free of precious metals and recyclable. In particular, its diaphragm is a microporous membrane, not a proton exchange membrane.

Secondly, it has the advantage of longevity. Both the positive and negative electrolytes are zinc bromide solutions.

There is no cross-contamination of the electrolyte, and the theoretical service life of the electrolyte is unlimited.

The statement refers to the service life of the electrolyte only.

If we consider the entire stack, the flow of zinc-bromine liquid has lower cycle times compared to the flow of all-vanadium liquid and iron-chromium liquid.

The stack of this battery can undergo more than 3,000 deep charge and deep discharge cycles, which is significantly lower compared to the all-vanadium liquid flow and iron-chromium liquid flow batteries.

Power outages scene application:

From the perspective of power outages application scenarios, the energy storage capacity range of flow batteries is relatively wide.

The smallest capacity is around tens of kilowatts, while the largest capacity can reach close to 100 megawatts.

In terms of duration, flow batteries can be classified as a form of long-term energy storage.

It is highly suitable for long-term and large-scale energy storage in grid power stations.

The main approach is to establish a new power system that combines new energy (photovoltaic/wind energy) + energy storage.

The vanadium liquid battery can achieve long-term energy storage relatively easily and conveniently due to its unique scalability characteristics.

This means that the battery capacity can be increased by simply adding more electrolytes.

Advantages, such as ultra-high security, are also applicable to specific industrial and commercial scenarios.

Vanadium liquid batteries are also suitable for industrial and commercial energy storage users with high safety requirements, long discharge times, frequent use, and high operating temperature.

Such as chemical parks, industrial buildings, commercial plant buildings, etc.

In the context of long-term energy storage, flow batteries can effectively address the issue of power outages and hold significant potential.

The industry generally believes that 2023 is a critical period for the commercialization of vanadium redox flow batteries.

PVMars also expect capital, technology, policy, market, and other stakeholders in the field of vanadium liquid batteries to collaborate in promoting the industry’s development.

Disadvantages of Vanadium Redox Flow Battery( VRFB ):

1- The energy density is not as high as that of lithium batteries.

Compared to lithium batteries, the energy density of vanadium liquid batteries is much lower.

2- High initial investment:

The initial investment cost of a vanadium liquid battery is high, with the main expenses being the cost of the electrolyte and stack.

But as the energy storage time increases, only the cost of the electrolyte needs to be increased, and the electrolyte can be recycled indefinitely.

Therefore, overall, as the scale of usage increases, the overall cost of batteries shows a downward trend.

3- When the temperature at the application site is too high, the cost of usage will increase.

When the temperature exceeds 45 degrees Celsius, vanadium pentoxide precipitates readily form.

If this scenario requires its application, a temperature control system must be installed, and regular inspection and cleaning will be necessary, thus increasing the cost of usage.

Generally speaking, different batteries have their own advantages and disadvantages, and there is a wide variety to choose from.

And there are constant changes in new energy storage technologies, corresponding to different commercialization scenarios.

From a commercialization standpoint, the industrialization process for the all-vanadium redox flow battery is faster.

In the future, in the field of energy storage, flow batteries will occupy an important leading position in the energy storage market above 1MW level.