Battery health check requires a series of detection systems to obtain accurate results. This system refers to the equipment used for testing both individual battery cells and complete batteries.

The purpose of testing is to confirm whether the indicators are normal, determine if they can continue to be used, and prevent accidents that may be caused by certain factors.

Whether it is a short circuit, overcharge, needle stick, impact, or burning, it should not cause an explosion due to fire.

Related devices for a battery health check:

1- Check the insulation resistance of the battery cell.

In terms of structure, it is necessary to ensure insulation between the positive and negative electrodes of the lithium battery, as well as between each electrode and the external housing.

If the insulation is not guaranteed, meaning that the insulation resistance is insufficient, there may be a risk of fire. We typically use the following equipment:

- Battery Insulation Resistance Tester ST5520

- Megger SM7110

- Megger SM7120

Automatic insulation and withstand voltage tester, such as the 3153 model.

Because resistance leads to power loss, the battery heats up. Heat may shorten battery life or cause a fire.

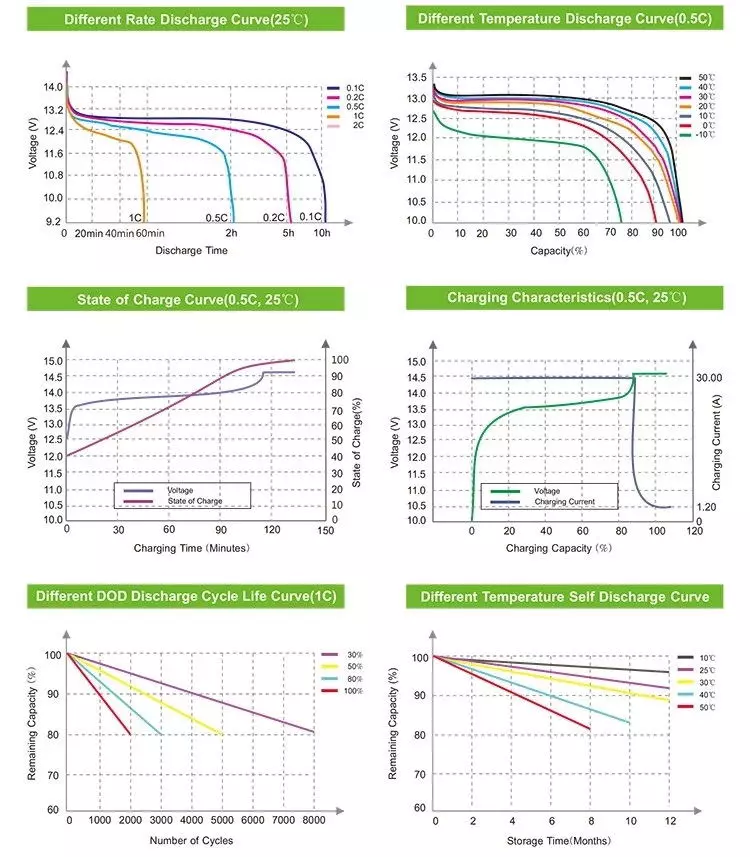

2- Voltage and temperature monitoring, during lithium battery charge and discharge test:

During charge and discharge, voltage and temperature are recorded to monitor changes in battery status.

The recorded data is analyzed to detect defective products and classify batteries.

For example, the memory recorder 8423 devices can record the voltage and temperature fluctuations of the battery cells in multiple channels.

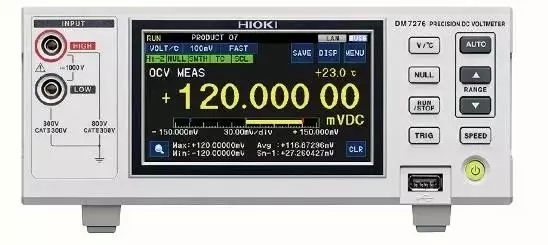

3- Check the open circuit voltage of the cell.

The battery voltage when no load is connected is called the open circuit voltage (Open Circuit Voltage).

Due to the characteristic self-discharge of the battery, the open circuit voltage value will gradually decrease. If there is a defect inside the battery, the self-discharge will increase and the open circuit voltage will drop below the specified value.

We use DC voltmeter DM7276 and battery impedance tester BT4560 to measure the open circuit voltage of lithium battery cells. By increasing the number of measurement channels, inspection times and production cycles can be shortened.

4-electrode resistance test system RM2610

The fine multi-point probe is in contact with the surface of the coating layer of the electrode sheet.

And the resistance of the coating layer and the contact resistance between the coating layer and the current collector can be obtained through a unique algorithm.

After drying, production deviations can be checked by spot inspection.

5- The safety of lithium batteries and the cause of loss of control

Checking the safety of batteries is not only about being free from sparks, explosions, etc. under various test conditions.

The most important thing is to ensure that the user will not be harmed when the battery exceeds the normal setting.

During the use of lithium batteries, chemical reactions constantly occur to generate a directional flow of electrons, providing continuous energy.

These chemical reactions also result in the generation of heat.

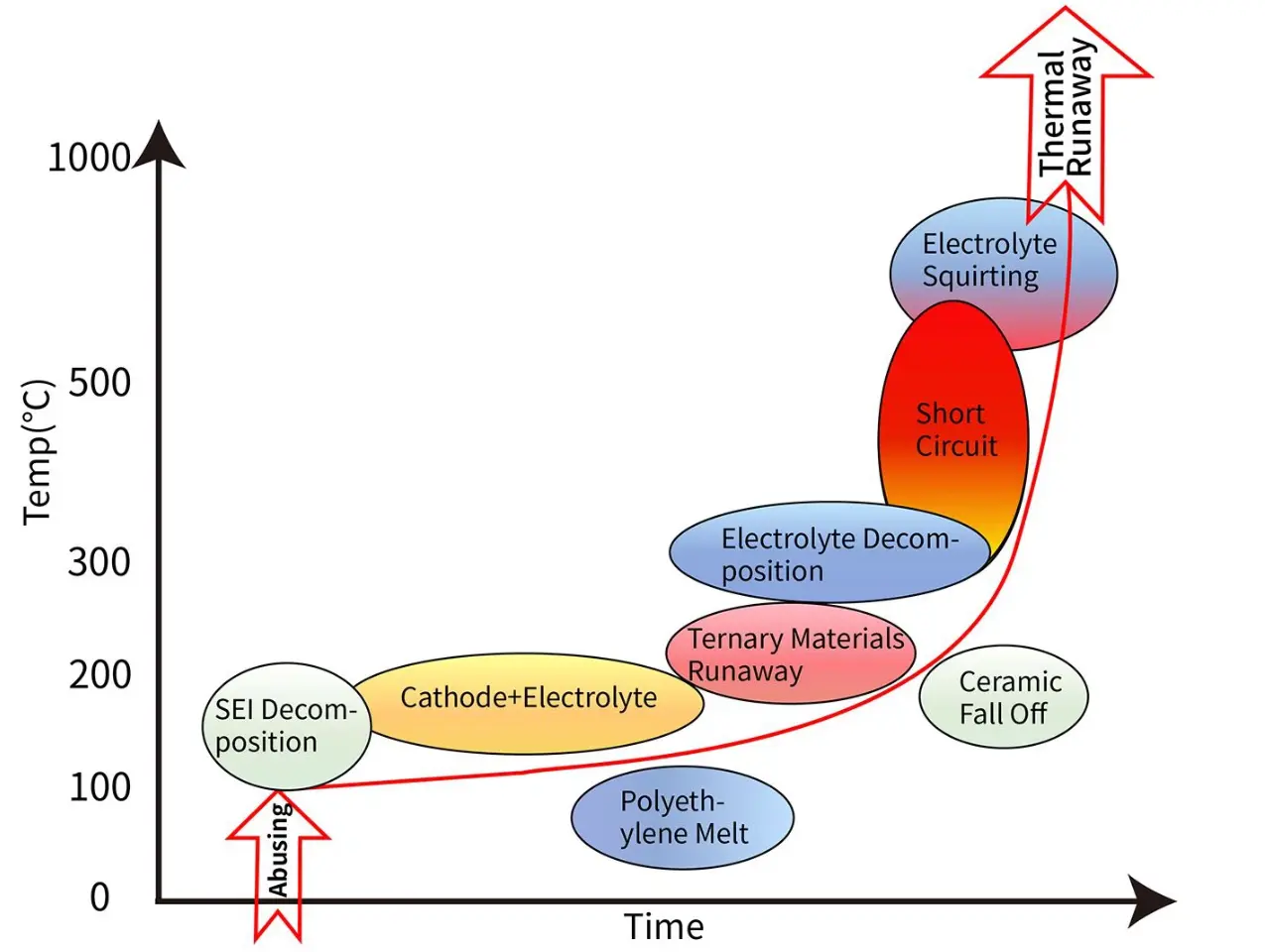

If the heat is not dissipated in time, it will lead to thermal runaway, which can cause battery damage, such as violent deflation, rupture, and accompanying fire.

Scenarios, where thermal runaway occurs, are as follows:

(1) In order to isolate the lithium-ion battery, the separator between the negative and positive electrodes is torn. This can lead to a short circuit, which often results in thermal collapse.

(2) The high ambient temperature leads to chemical instability.

(3) Other abuse operations, etc.

Some quick ways to battery health check:

Battery health check through related equipment can obtain relatively accurate data, to determine whether your battery is healthy.

But if you don’t have these devices, how else can you battery health check?

1- Use a multimeter to check whether the current output of the battery is stable

The operation steps are to find the positive and negative poles of the lithium battery, put the small metal rod at the end of the red cable on the positive pole, and put the metal rod at the end of the black wire on the negative pole.

If the output current is about 10a, it can output stably. After 1 hour, the value remains unchanged, indicating that the performance is stable and your lithium battery is of good quality.

2- Continuous discharge observation of lithium battery

When the lithium battery is connected to the load, it undergoes the process of discharging.

After continuous discharge for about 10 minutes, if the two terminals of the lithium battery do not become hot, it indicates that the protection system of the lithium battery is relatively intact.

In general, lithium batteries with a reliable battery protection system (BMS) are of good quality.

3-Auxiliary judgment based on battery hardness and touch.

A good lithium battery is fully charged, so if you press the middle part of the battery with your hands, there will be no collapse or limpness, and it is a healthy battery.

In addition, let the battery charge for 30 minutes. If the positive and negative poles of the battery do not become hot.

It means that the quality of the battery protection board is still relatively good, so the safety of the battery is high.

4- Judging the quality of lithium batteries according to their appearance and weight.

A good lithium battery will not be light and light. Although its weight is lighter than that of a lead-acid battery, it must have a certain sense of heaviness compared with similar batteries.

From the appearance point of view, a good lithium battery will be fuller, and the workmanship will be more refined.

Suggestion:

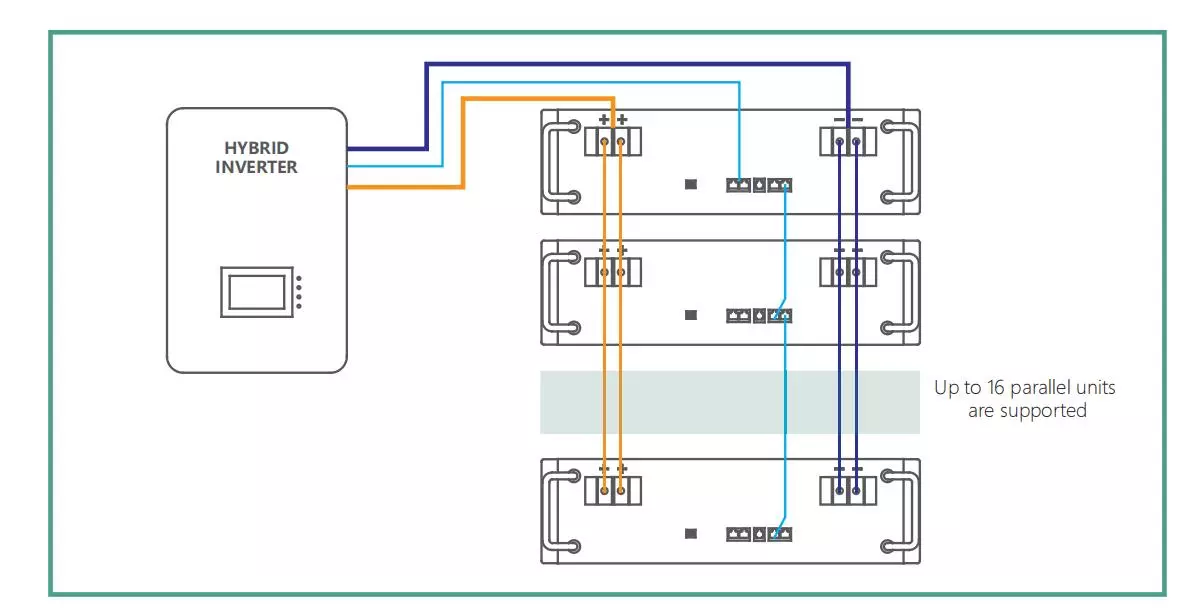

With the gradual expansion of the application range of lithium batteries, it is becoming more and more mature in fields such as solar energy, wind energy, and electric vehicles.

The energy density of a single battery is increasing, resulting in higher volume. Additionally, the capacity of batteries is also growing.

If the quality is not up to standard, it is prone to explosions, leading to an increasing number of dangerous accidents.

Therefore, before making a purchase, it is important to find a lithium battery that is produced by a reputable manufacturer and has a valid test certificate to ensure its safety. Such as TUV, CE, MSDS, etc.

If you are still interested in learning about the charging issues and application scenarios of lithium batteries, you can click on the highlighted orange text to find out more.