For solar energy storage systems, the core is storage of electricity, so what do we use to store power?

For 16 years, we have used the German 5S technology standard to produce solar energy systems.

5S is a management approach method that stands for sort, set in order, shine, standardize, and sustain. It is used to organize and improve work areas, and it can be applied to solar clean energy to improve efficiency, safety, and productivity.

In PVMARS solar power factory, by sorting and marking each kind of part and uploading the data to the computer, workers can easily find the corresponding parts from the raw material inventory through marking whenever they need, and the inventory data will change accordingly, improving the overall production efficiency.

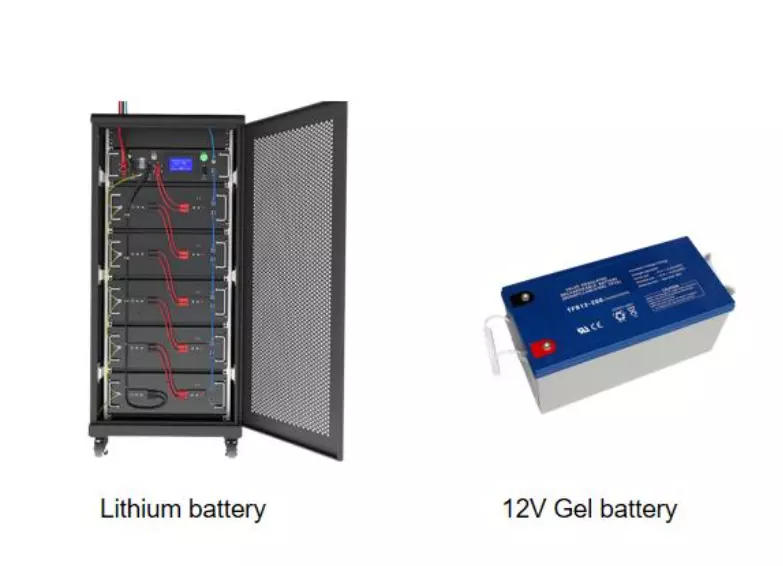

The core is storage of electricity, we used quality battery to store power

Solar systems common use lead-acid batteries (gel batteries), lithium batteries, and flow batteries for store power.

Click on the orange font to jump to the production video and more production details.

Lead-acid batteries (gel batteries) are the most common battery in solar systems. They have a more competitive price, a depth of discharge (DoD) of 70%, up to 1500 cycles, a service life of generally 4-6 years (depending on the actual use), and are generally suitable for small families.

Lithium batteries are more expensive than lead-acid batteries (gel batteries), DoD 90%, cycle times up to 3000 times, service life is generally 6-8 years (depending on the actual use), their energy density is high, lighter than lead-acid batteries (gel batteries), generally suitable for homes, factories, farms and so on. It is also PVMARS solar’s best-selling battery.

Flow batteries are an emerging type of battery that is not yet as widely used as lead-acid (gel) or lithium batteries.

The advantages of this type of battery are that as compared with other types, it maintains 99% DoD, can cycle up to 10,000 times, and has a service life of 10-15 years (depending on the actual use), it is aqueous, won’t explode in accidents, and it is highly safe.

But at present, it can only be used for large-scale solar energy storage projects, because such batteries are large, like lithium batteries and gel batteries, so they cannot be widely used.

PVMARS Solar will continue to innovate in the future to bring better energy storage technology to more people.

Battery Raw Materials Supply System ( for example, gel battery ) :

PVMARS solar has a special procurement department.

For the battery housing, our raw materials meet the UL94HB and UL94V-0 standards of ABS materials, no color difference, No crack using high quality lead calcium grid, reduce gas precipitation, reduce the corrosion rate.

Prolong the service life of the battery with high quality copper terminal, excellent conductivity and high wear resistance, Enhance the high current discharge performance of the diaphragm adopting high quality AGM, improve the heat dissipation capacity and so on.

Battery Production System:

In strict accordance with 5S technical standards, our production workshop has marked the production time, model and positive and negative electrode marks for each battery plate. This is to effectively ensure the quality of the plate.

Using semi-automatic plate wrapping machine, semi-automatic double plate wrapping process, double partition can better prevent short circuit of the plate, and semi-automatic double plate wrapping process can ensure that the package out of the pole group is neat, aesthetically pleasing, clean.

Automatic grooving machine is adopted, which has higher efficiency, saves the process involved in manual grooving, avoids artificial contact with the pole group, and protects the pole group to the maximum extent, so that the battery has very good self-discharge performance, battery consistency and total voltage consistency.

Battery QC System:

The DC spectrometer detects lead purity in the battery with high precision to ensure purity is above 99.994%. The battery that passes will be marked and then the next step will be carried out.

Use a large current detection machine to ensure that each of the batteries has the largest current. Check whether the charge and discharge is normal, whether the battery bus is dissolved, short circuit bad situation, check all faulty factors.

Use the internal resistance meter to ensure that the internal resistance and voltage of each battery are normal, and the battery consistency. After passing this series of tests, the next round of the production system can proceed.

Battery Packaging System:

Generally, cartons are used for packing. If you need, we can also pack them in wooden cases, and then the goods will be shipped on pallets printed with the steamed and smoked logo.

Battery of the Factory Inspection System:

Before each loading and shipment, our factory has special personnel to check QC inspection of qualified products. They distinguish and mark the area to place, ensure the shipment quantity, model, customer name is accurate, only after the standard is allowed to load containers. Ensure that you receive complete and correct goods at the end.

General battery in the warranty period, if there are any quality problems, will unconditionally replace the replacement battery. For example, a gel battery bulge, confirm the quality problem, will directly transport a gel battery for you to replace. If you want to know what kind of quality problems may occur with the battery, please contact us.

We discussed that batteries are the core of solar energy storage systems. So besides the battery, what are the main parts that make up such a complete solar energy storage system? That’s right, a solar inverter.

Classification and production system of solar inverter

Of course, there are many kinds of solar inverters. For example, you may have heard of grid-connected/on-grid inverters, high frequency inverters, power frequency inverters, off-grid inverters, portable inverters etc.

But in this time, we mainly tell about the solar energy storage inverter( IGBT Solar Inverter ).

It has a lot of aliases – power frequency/pure sine wave inverter, high frequency inverter, off-grid inverter, portable inverter, etc., is not familiar, these are the last paragraph described, in fact, they also can be used in the solar energy storage system.

The principle is similar, the photovoltaic panel or battery direct current into alternating current, the output of alternating current to 220VAC, 230VAC, 380VAC-480VAC and other equipment for use, in solar power generation system is also crucial.

Each product has its own production management system, such as Inverter Raw Materials Supply System:

Our attitude towards raw materials is that we would rather spend money and time purchasing different brands on a large scale for testing, rather than sacrifice users’ trust in us and take the risk of using raw material suppliers that have not been tested.

Through our testing and application over the years, here are the brands we often work with:

MOS tube — imported from the United States IR brand,

Silicon controlled — Semikron, Germany

IGBT module — Mitsubishi brand in Japan

Inverter Production System:

For the PCB plate inside the inverter, we use an automatic machine plug-in to improve efficiency, reduce loss, avoid manual errors and strengthen stability.

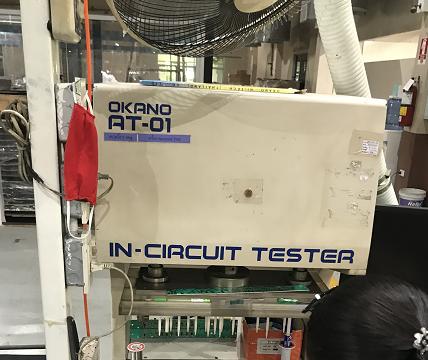

Inverter QC System:

AOI equipment and ICT are used to detect the state of each PCB board, whether there are cracks, pinholes are aimed at the PCB board, all lines are checked, and the failure rate is reduced.

The PCB board with problems is automatically summarized into the wrong box, and the PCB board with passed quality will be installed in the next round of accessories.

In addition, our production department will prevent AOI equipment omission. Manual spot checks are also conducted to ensure quality.

Inverter Packaging System:

All our packaging and products are OEM customized, can be silk screen printed or stickers exclusive to your company logo.

1kW-5kW inverter models in carton packaging, containing pearl cotton

5kW-500kW inverter models in plywood wooden box packaging, containing pearl cotton. One piece in one package.

MW level projects will be transported in ESS containers, and the interior will be upgraded and reinforced. We will have professional engineers ready to answer your questions about MW level solar energy storage systems.

Inverter of the Factory Inspection System:

We generally use no less than 100 times the limit failure test.

Through user feedback statistics, 100% of the tested machines can work stable.

Inverter After Sales Service System:

Different from batteries, there are different PCB boards inside the inverter.

We have corresponding maintenance mechanism for different PCB boards. Within the warranty scope, after IOT data or online remote detection, you can find which PCB has a problem.

We will send the corresponding replacement of a new PCB board or more spare parts for free, and PVMARS has a video to replace different inverter parts, so that you do not have to worry about maintenance problems.

In addition to the battery, the inverter, there is also the most indispensable part of the solar energy storage system that everyone can think of, the SOLAR PANEL.

Classification and production system for solar panels.

There are many different types of solar panels on the market, polycrystalline (poly) PV modules and Monocrystalline (mono) solar modules.

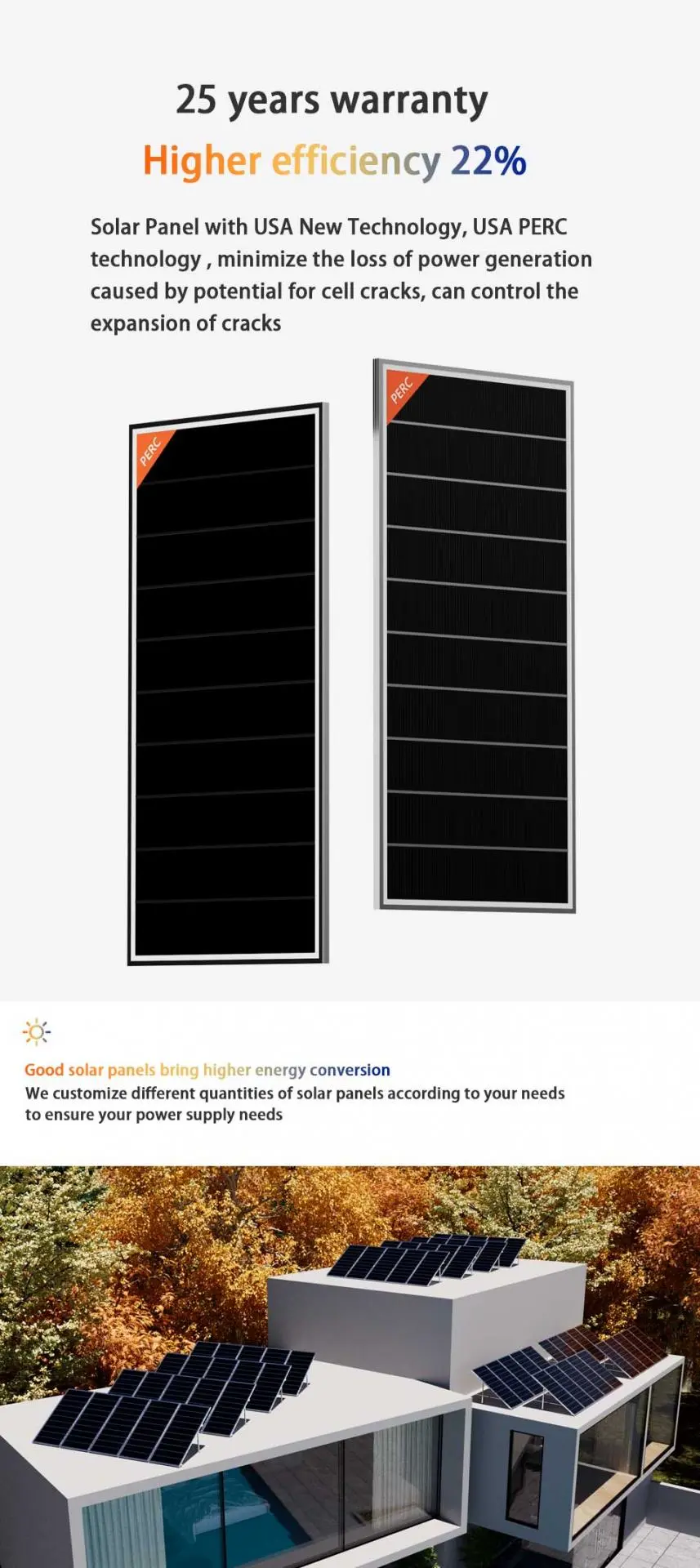

Currently, the mainstream is monocrystalline photovoltaic panels, which are often configured in PVMARS solar energy storage systems.

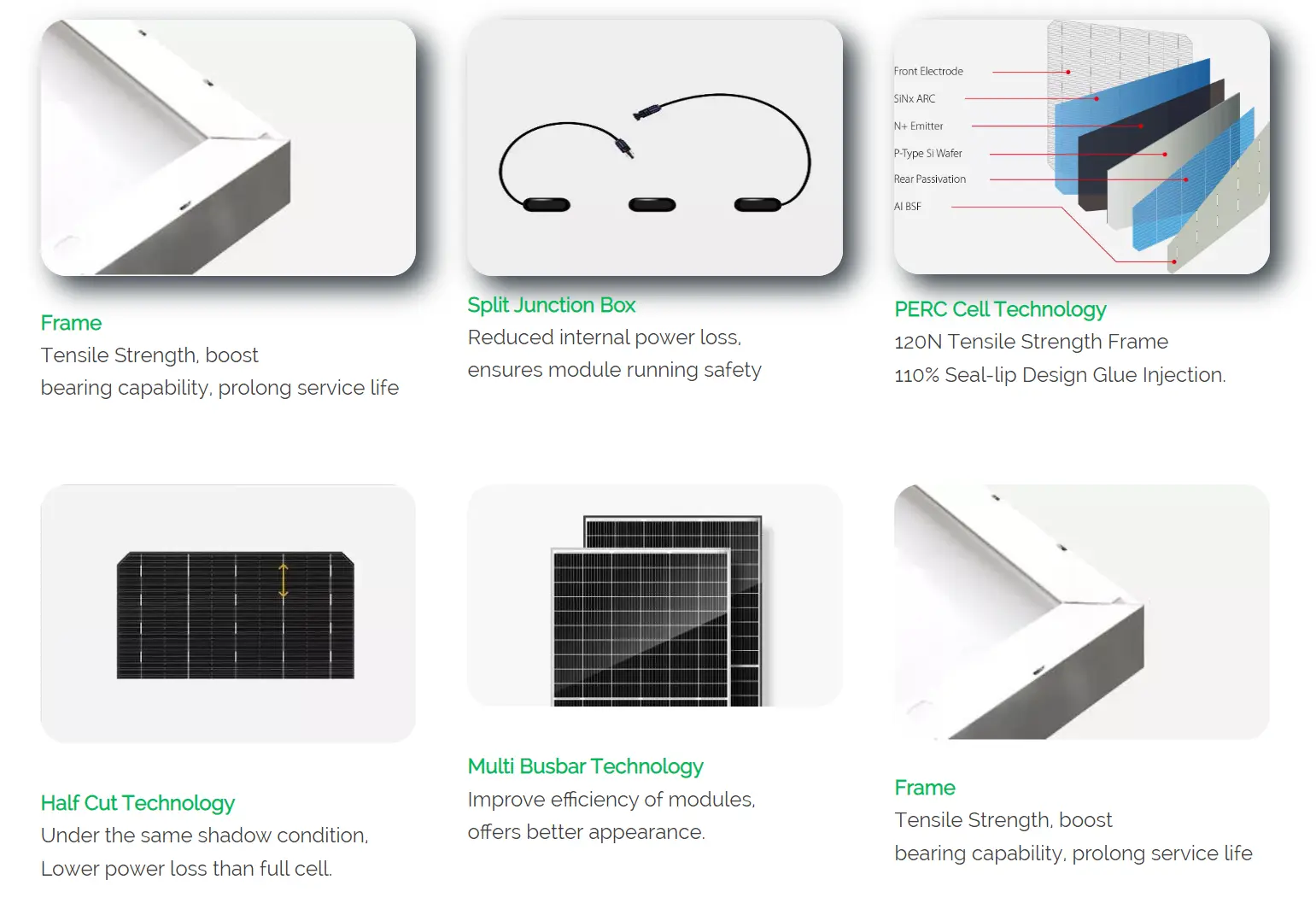

Monocrystalline ( mono ) PV panels are divided into many categories, such as PERC solar panels, half-cell solar panel, all black solar models, flexible solar panels, bi-facial photovoltaic panels, shingled/HJT solar modules and so on. These varieties can be found in the PVMARS solar power factory.

So what production standards do we have for photovoltaic modules?

Solar Panel Raw Materials Supply System:

Each photovoltaic panel is made up of a crystalline silicon wafer, which is one of the raw materials we can see with the naked eye, along with glass, aluminum and polymers.

Cooperating supplier brands include: LONGI, CanadianSolar, Suntech, JinKo, etc.

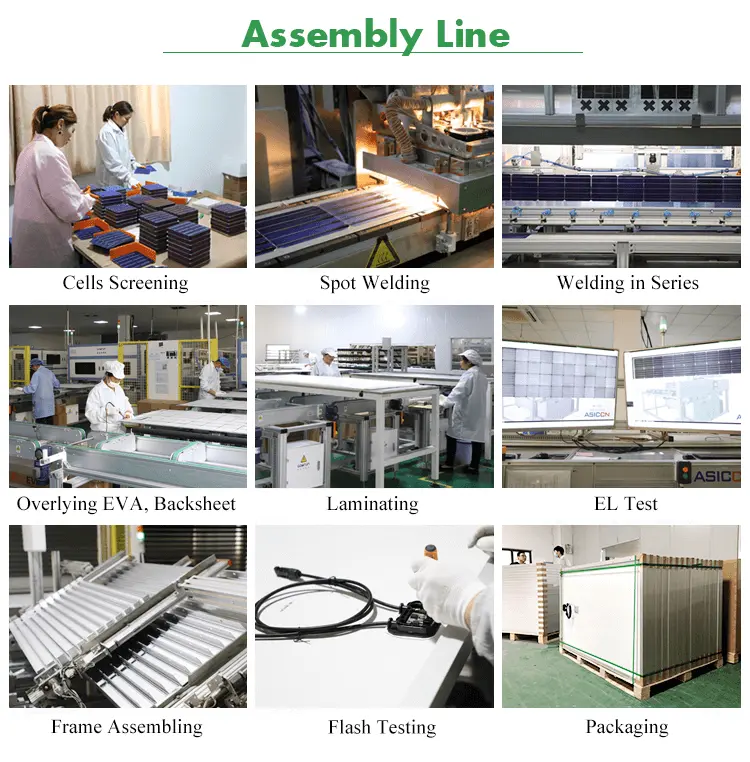

Solar Panel Production System:

Automatic sorting equipment classifies cells by color and power/efficiency

The EL test was conducted on the battery cell through the EL device to ensure the battery cell was not cracked

Components use fully automated production line operation, for more production videos, please click the orange font to view

Solar Panel QC System:

Test the solar cell with an EL tester to ensure no cracking

The component tester performs EL and data testing before the component is packaged to ensure that the data is qualified. In addition, the component is not cracked

Component products are monitored by testing instruments to ensure correct data.

Solar Panel Packaging System:

It can be packed in cartons or wooden cases, which can be customized according to your requirements.

PV modules adopt a vertical packaging mode to reduce transportation damage.

Solar Panel Factory Inspection System:

PVMARS professionals check whether it is qualified, identify the marking zone placement, and ensure the shipment quantity, model, customer name, etc. Ensure that you receive complete and correct goods at the end.

Solar Panel After Sales Service System:

PVMARS is a problem-taking company, offering a minimum 25-year guarantee on solar panels’ efficiency output. During the 25-year warranty period, if there is a quality issue, such as a problem with the battery, the solar modules will be replaced with a whole replacement one free of charge.

These are the main components of a solar energy storage system, and of course there are other accessories. For example, PV combiner box, solar controller, bracket/rack, cables and every system will provide installation tools.

In order to maximize your rights and interests, we have always tried our best to imagine for you in all aspects, only what you can’t think of, nothing we can’t do.

Believe in PVMARS, you deserve it.

PVMARS Solar’s vision: a community with a shared future for mankind, contributing to the harmonious coexistence of mankind and nature.

Mission: To enable everyone to use renewable energy, achieve electricity freedom and independence.

Values: Passion, professionalism, warmth, innovation.

Advantages: Focus on user demand, use IOT and advanced solar energy storage technology, competitive price, global installation service.