Getting wind turbines to work efficiently and perform well is crucial for your ROI. To ensure these units can generate electricity efficiently, we have conducted a series of rigorous tests.

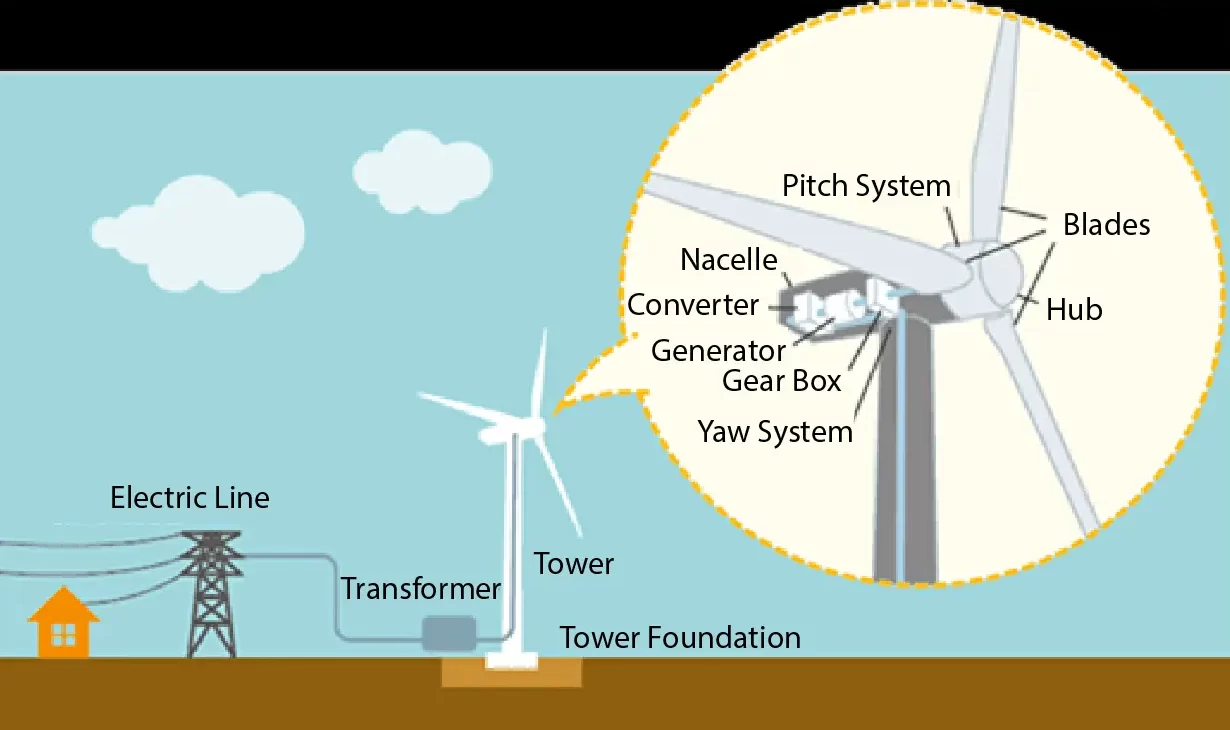

The core of a wind turbine is its main cabin (generator), which is a key link in converting mechanical kinetic energy into electrical energy.

In addition to the main nacelle, wind turbines also contain multiple other precision components whose synergy determines the entire system’s performance.

At PVMars, we are committed to providing our customers with the highest quality products and services.

For this reason, we have specially produced factory test videos to show the rigorous testing standards that wind turbines undergo before transportation and installation.

In this video, you’ll learn more about how we ensure every wind turbine meets the highest standards to bring you reliable, efficient green energy solutions.

Among them, the testing of wind turbines mainly includes the following 6 elements.

1- Rotor balancing test of wind turbine

By installing sensors on the wind turbine rotor, the balance of the rotor can be tested.

Because an unbalanced rotor can cause vibration and noise, reducing the efficiency and life of the wind turbine.

2- Power performance testing of wind generator

In the video, we show how small wind turbines can withstand rigorous testing from a starting wind speed of 2m/s to a wind speed of 10m/s indoors.

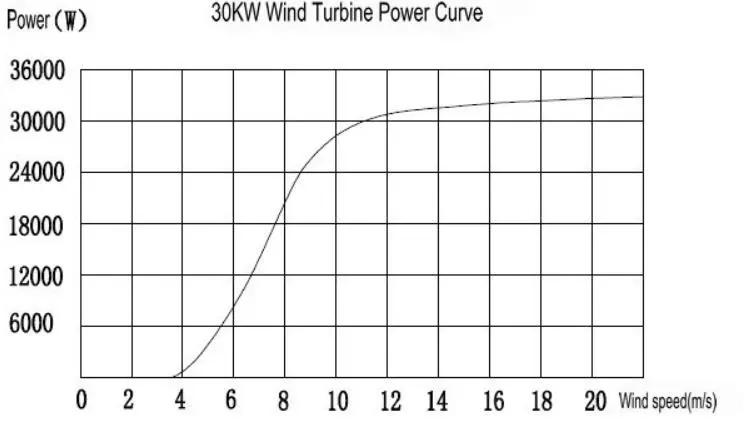

This process aims to accurately evaluate the power output performance of wind turbines at different wind speeds.

These data are the key basis for drawing power curves, truly simulating power generation scenarios, and providing strong support for practical applications.

Through these experimental data, we can accurately predict the daily power generation of wind turbines in various application scenarios. Whether it is factories, homes, hotels, or, schools, thereby helping you make more informed energy choices.

It is particularly worth mentioning that for areas with average wind speeds below 5m/s, PVMars strongly recommends that you consider solar systems.

Or wind-solar hybrid systems to maximize energy utilization efficiency and ensure that your energy needs are met stably and efficiently.

3- Electrical performance testing of wind power systems

Including electrical parameters such as voltage, current, frequency, etc. to ensure that the fan meets the design requirements. Large wind turbines are usually tested outdoors.

4- Mechanical performance testing

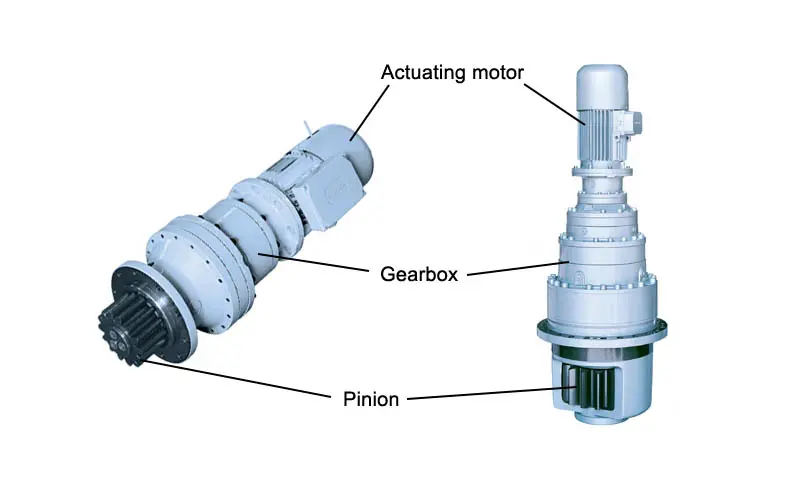

It mainly tests the operating status of mechanical components of wind turbines, such as bearings, gearboxes, etc.

Like the rotor balancing test, data is captured while in motion. Finally, verify whether the comparison data is correct, which means the test has passed.

5- Wind field condition adaptability test

Let wind turbines compare their operating performance under different wind speeds, wind directions, and temperatures to evaluate their ability to adapt to different wind field conditions.

6- Communication system testing

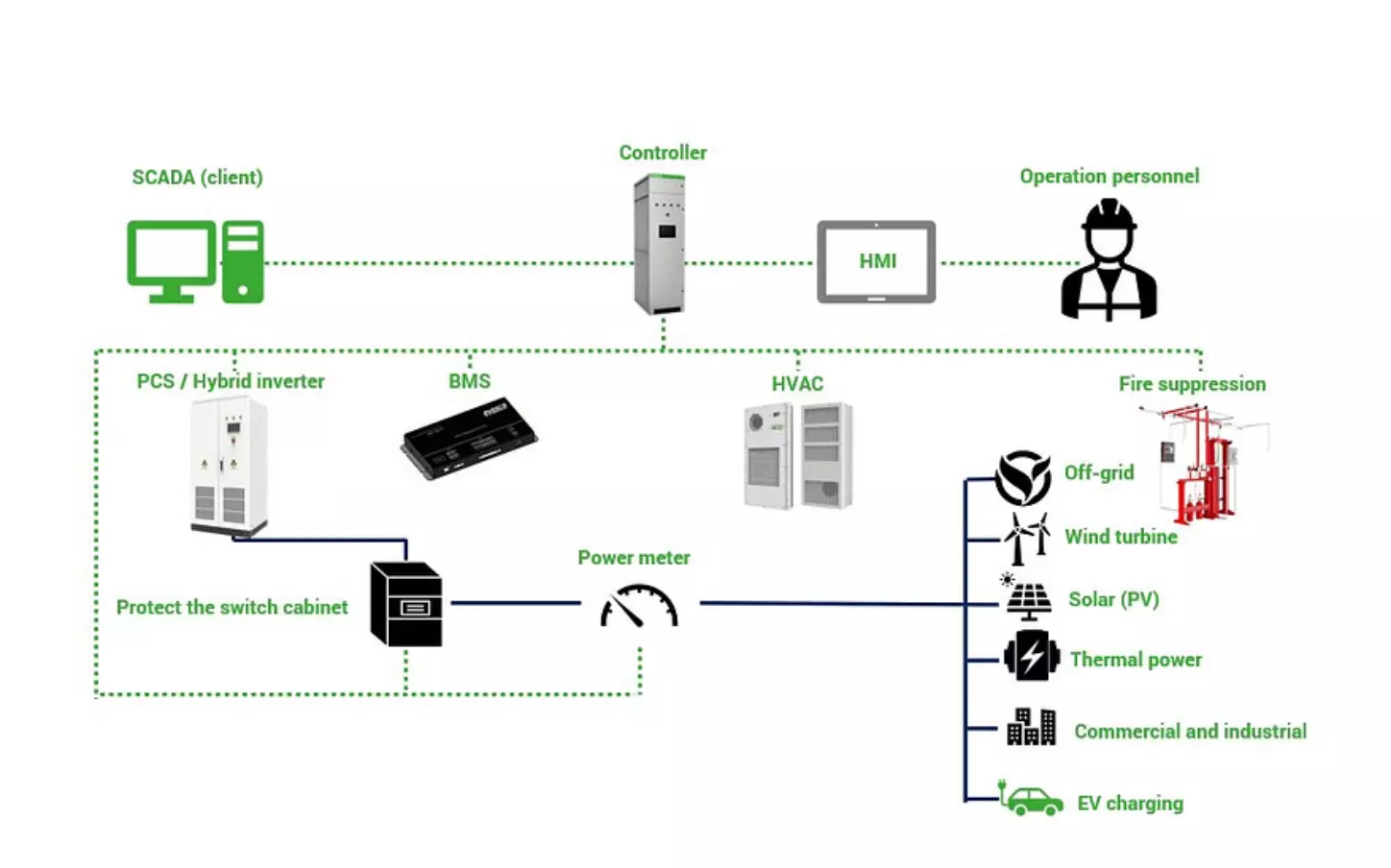

This test will connect the ventilation controller, inverter, etc. to check whether the monitoring system, remote communication system, etc. are working properly.

Summarize

In a fiercely competitive market, although price is the focus of consumers’ attention, the corresponding product quality, professional services, and perfect after-sales system cannot be ignored.

Consumers always expect the products they buy to be value for money, not just in terms of price, but also in terms of durability and performance. No one is willing to sacrifice long-term user experience for temporary convenience.

At PVMars, we are well aware of the close relationship between price and quality, so we insist on providing customers with excellent quality that matches the price.

To ensure your investment is worth your money, we encourage you to conduct a comprehensive comparison and consideration before purchasing.

PVMars will provide you with detailed test results and professional service support, making you more informed and confident in the purchase process.

We firmly believe that only products with excellent quality and considerate service can win your trust and satisfaction.