Are you worried about the efficiency of solar panels? If you are using solar panels, probably the biggest resistance is that photovoltaic panels will reduce power efficiency, power, wattage, etc. As the temperature rises.

Many users think that if they buy PV modules, they can certainly emit the same power, 600 watts solar panels =600 watts of power?

The answer is no.

Under the sun, as the temperature rises, any object will produce high temperatures, and solar panels are no exception.

While absorbing the heat and radiation of the sun, the photovoltaic module also generates heat energy, which is the source of the solar panel’s inability to normally produce the same power of electricity. Without the intervention of other equipment, it takes a long time to dissipate (such as one night).

Isn't there a way to fix it?

Our answer is that there are ways to do it. Before we get to that, let’s understand how a solar panel is created.

Solar template production steps

1-Welding process

The Stringer automatically welded solar cells are connected in series through ribbons.

The welding machine will recheck the cell chip and the quality by cameras while waiting and reject unqualified cells.

Our staff will always follow this up with a manual inspection too. In this process, the critical control point is the cell peeling test.

Our quality engineers perform the peel test every 12 hours.

2-Laying up the process

The machine puts the cell string on EVA.

EVA is a kind of encapsulated material that is melted at high temperatures and covers all materials together providing protection for solar cells.

EVA should be laid in the center to make sure it can cover the whole glass after lamination.

The lay-up staff rechecks welding quality mainly focusing on welding strip shifting and cold soldering.

3-EL Test

Doing 100% onsite EL test is another critical part. EL test is used to detect defects in modules such as micro cracks, fragments, cold soldering, and so on.

As a result, it is necessary to ensure control and rework for unqualified modules in order to ensure quality. In order to analyze the defects, it is necessary to record them and send them to the former process for review.

Afterward, the qualified module moves on to the next process.

4-Lamination

The modules are laminated under a vacuum to suck out any air bubbles. They are also laminated with the correct lamination recipe to ensure that the EVA fully covers and protects the cells.

In this process, EVA gel content and pulling strength between EVA and the Glass/Backstreet are carefully controlled.

As long as the control points are checked and the results are good. We have qualified the laminates and moved on to the next step.

5-IV Test

We do 100% safety tests including Grounding, Insulation, and Hi-pot tests. IV Test.

The modules are then passed through an IV tester which detects the power of the module and labels it as a nominal power that is directly related to the final factory price.

We deploy IV-testers that have passed AAA certification from a reputable institute to make sure that the power we sell is real power. Simultaneously, we do the final EL testing which ensures that our products are qualified and up to our quality standards.

6-Visual Inspection Before Packaging.

Toward the end, we do a final visual inspection before packaging.

Qualified modules are sorted and packed on pallets by the same current, color, and power.

After going through these various processes you get the finished modules It fully demonstrates intelligent and futuristic manufacturing.

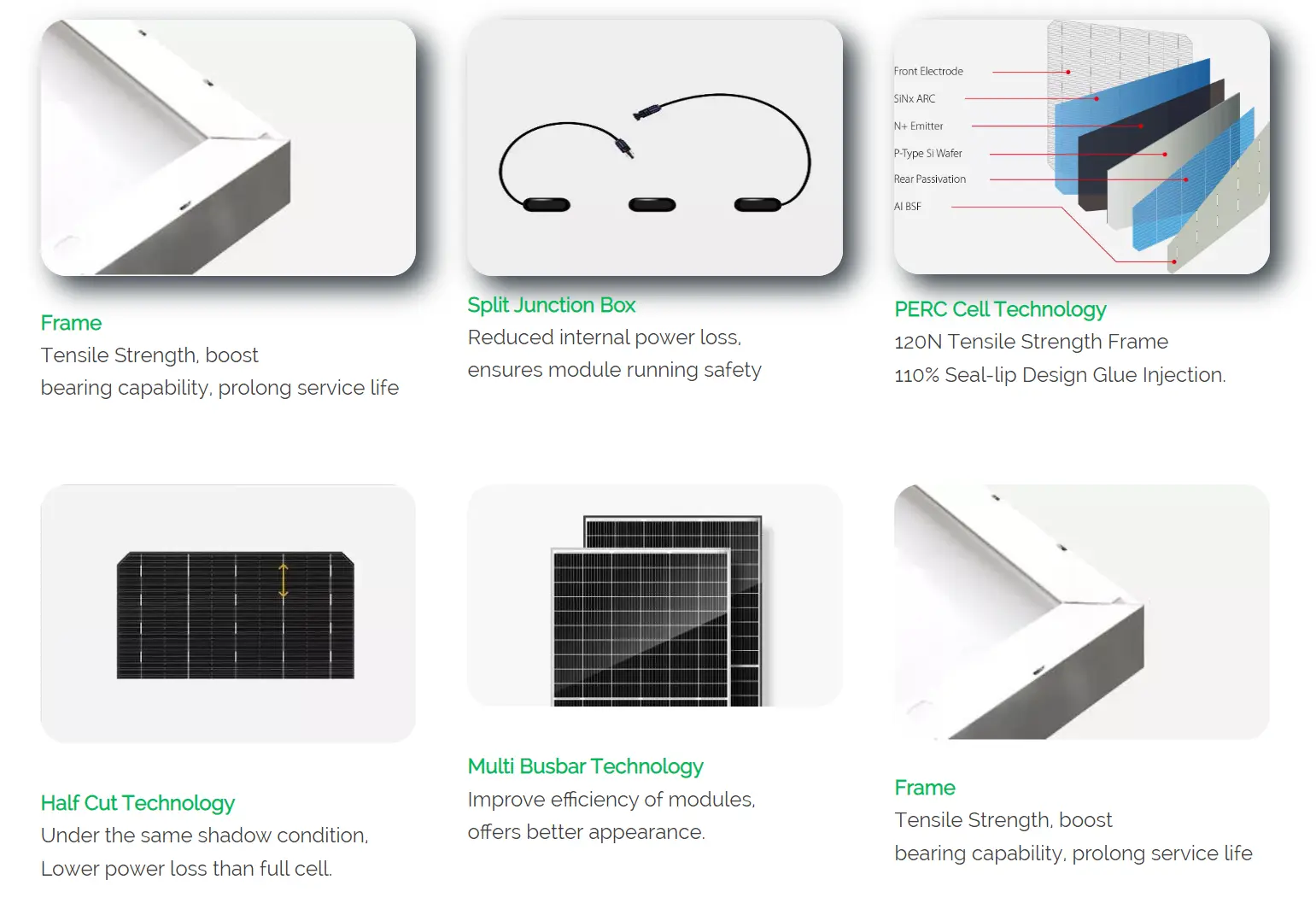

Feature

Intelligence is one of the biggest features of the workshop. We have illustrated it through automatic manufacturing.

Advanced testing equipment

Automatic transportation system

Information technology

In the future, the workshop will introduce the AGW robot for cell transportation and launch automatic binning & packaging equipment.

Paperless management is another feature of the intelligent workshop.

All production and quality data can be generated in real-time and at the same time workers can get it online and make instant communication at any time in the workshop via iPads and cellphones. Supports the trial production of new cutting-edge technology modules before they go into mass production.

We are planning to upgrade the workshop by laying out PV modules on the roof aiming to build a digital flexible and zero-emission carbon-neutral factory in the near future.

By understanding the production process, we also understand that it is difficult for a single solar panel alone to solve the problem of low power generation caused by high temperatures.

Solutions

Current solutions to reduce the temperature of solar panels and improve the efficiency of power generation include water cooling technology and installing small fans for each panel.

PV magazine has published an article about active cooling through water cooling technology. Claims that its solution can boost the power generation of photovoltaic installations by 8% to 12% annually. However, additional special water pipes and sensors are required, resulting in increased installation and product costs.

This kind of solution is explained in more detail in the article Photovoltaic panel cooling by atmospheric water sorption – evaporation cycle.

At present, it is only suitable for large farms, industrial and commercial institutions.

Reduce the temperature of the solar panel and increase the total power generation efficiency

In addition to the above water cooling technology, we also further study new materials, such as coating a layer of special material on the solar panel.

The material will form a film when the sun shines on the solar module, and will reflect the energy that causes the panel to heat up to the sky, so as to ensure that the photovoltaic panels when absorbing the sun, get rid of the heating problem.

The overall PV module temperature is maintained at 20 degrees Celsius.

It is important to note that this technology is still under development, and we always hope to reduce the cost and return it to you.

We believe that in the future, we will continue to break down technical barriers and provide safer, cheaper, and more efficient photovoltaic products.

Believe in PVMARS, you deserve it.

PVMARS Solar’s vision: a community with a shared future for mankind, contributing to the harmonious coexistence of mankind and nature.

Mission: To enable everyone to use renewable energy, achieve electricity freedom and independence.

Values: Passion, professionalism, warmth, innovation.

Advantages: Focus on user demand, use IOT and advanced solar energy storage technology, competitive price, global installation service.